About us.

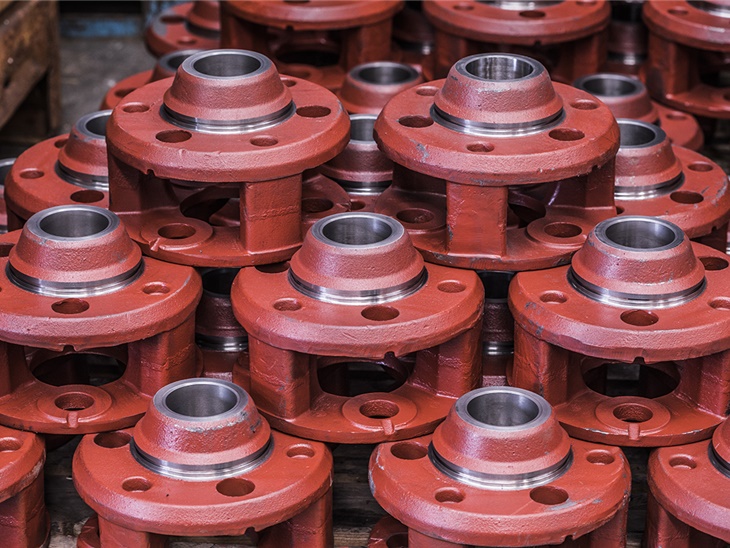

F.lli Severgnini mechanical workshop has, since 1954, been a protagonist of the metalworking sector for third parties. From generation to generation, the company has developed specific technical skills which, combined with constant technological innovation, has enabled it to have, as clients, some of the world's most important agricultural machinery manufacturers.

Precision, flexibility, assistance

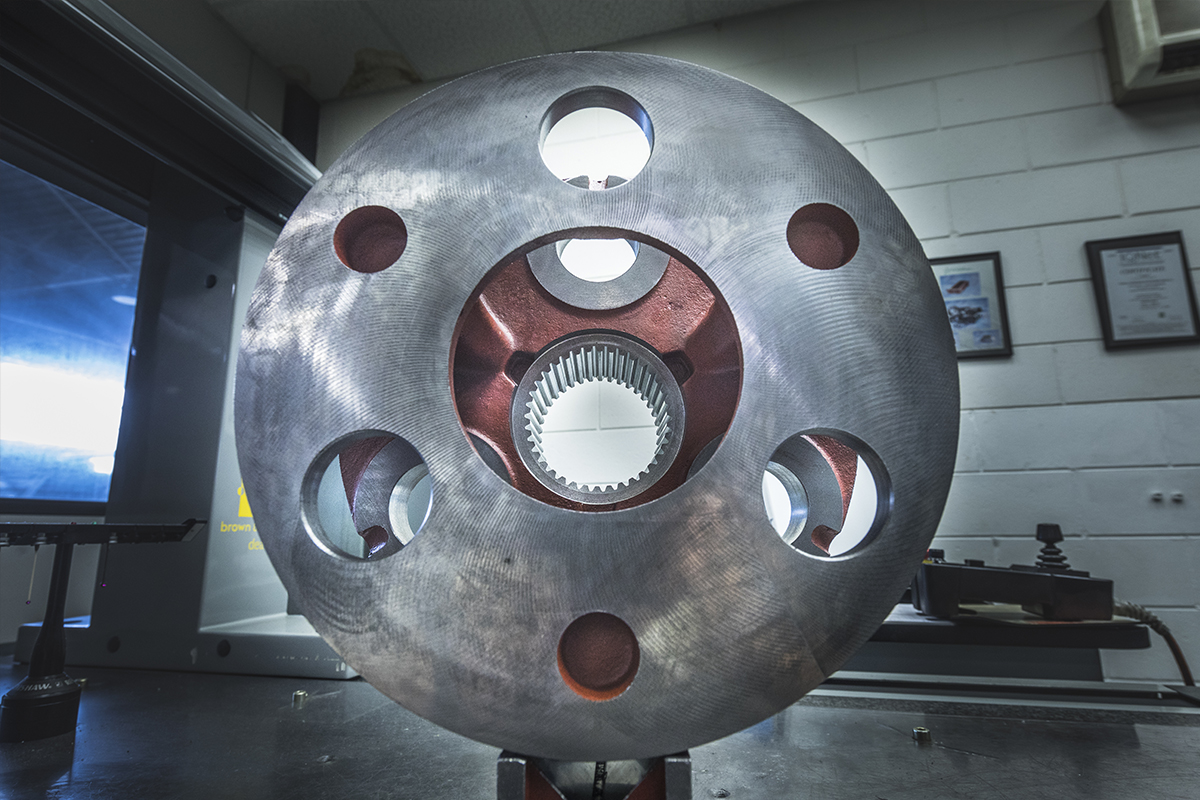

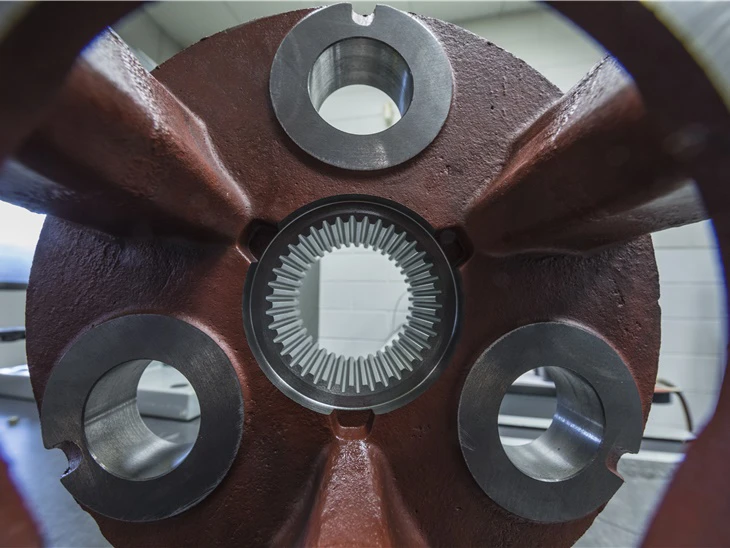

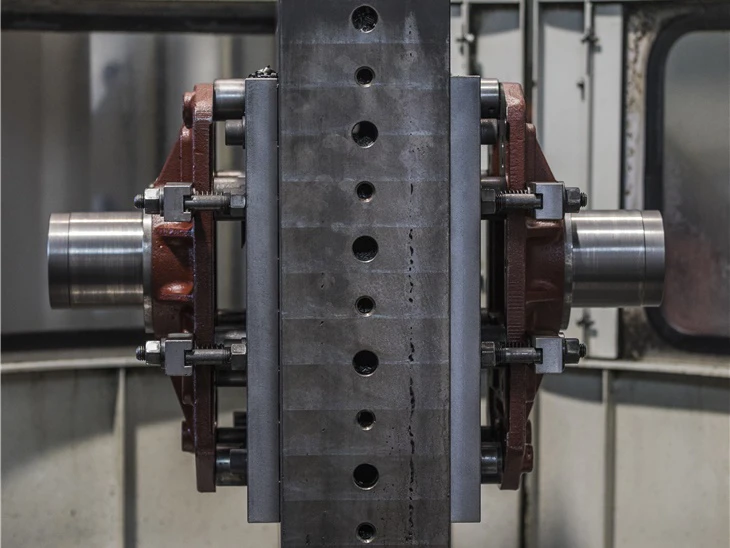

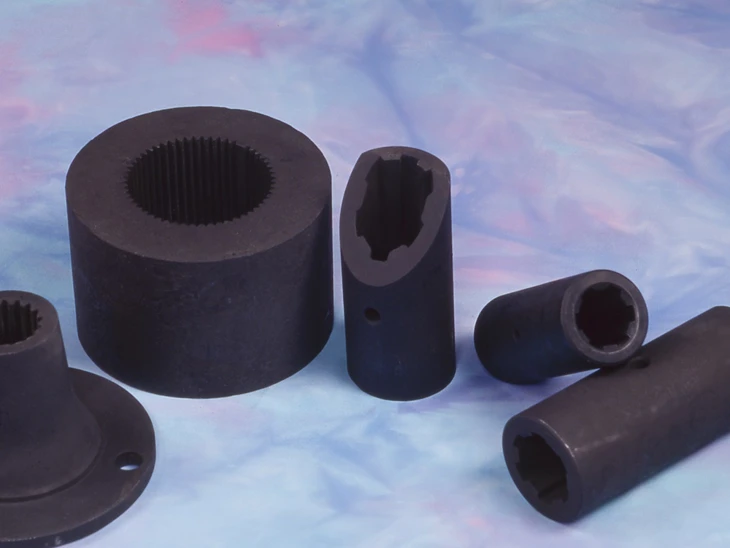

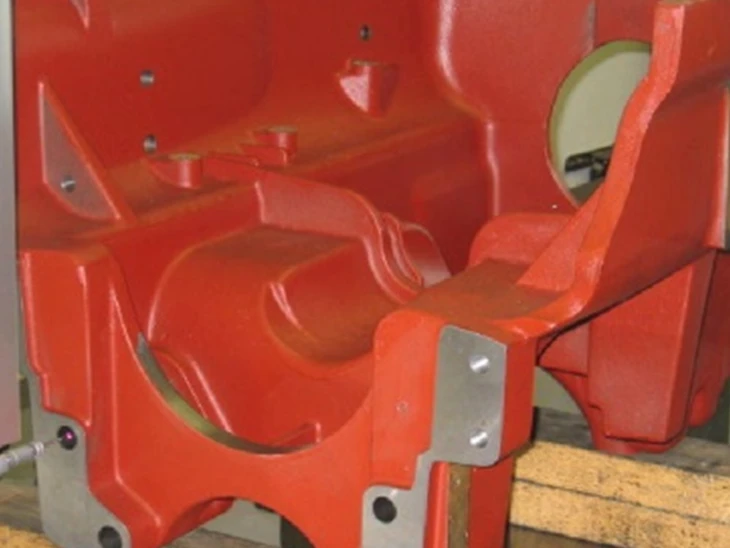

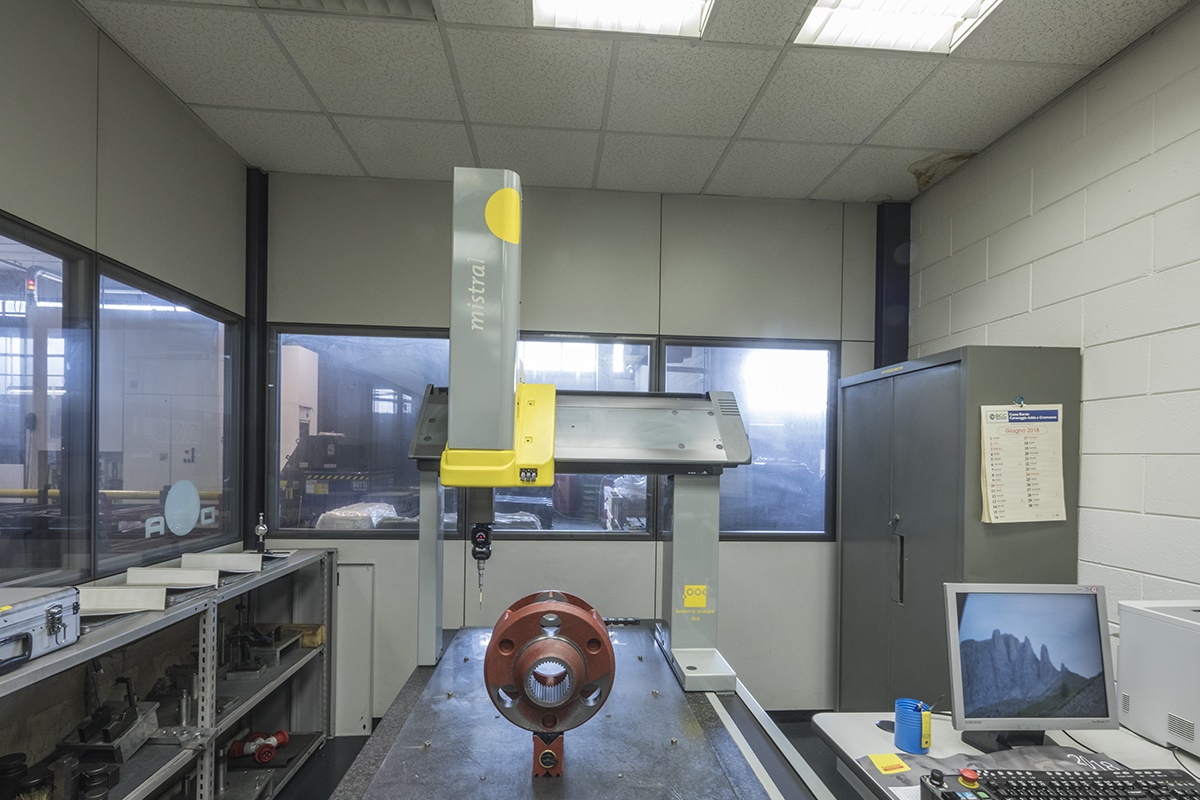

Starting from customers’ designs or projects, the production department carries out the required operations such as turning, broaching, milling and drilling, final inspection with 3D Dea Cnc measuring machines, for the realization of small and large series, providing, when required, surface heat treatment, high-frequency tempering, galvanic treatment and painting through a network of tested suppliers. Thanks to a tried and tested organization, combined with technical expertise, we guarantee compliance with delivery times, providing advice during sampling, to optimize the items when necessary.

Quality

Client satisfaction is the primary goal of F.lli Severgnini S.r.l.

Work quality is guaranteed by certified in-house process control.

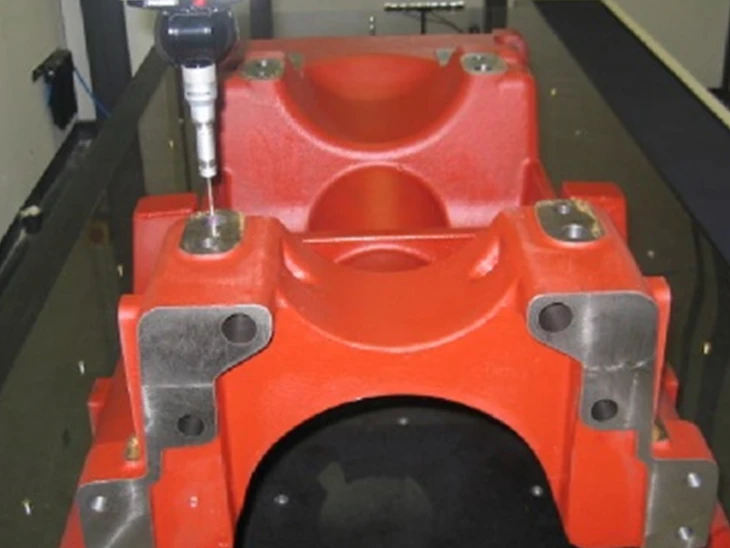

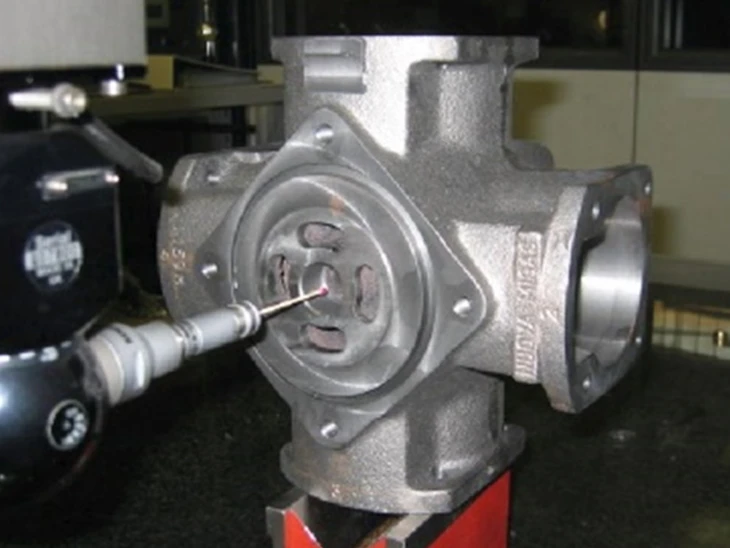

Controls are carried out independently by each operator, both using appropriate measuring instruments on board the machine, and through the use of three-dimensional inspection machines in a dedicated room.

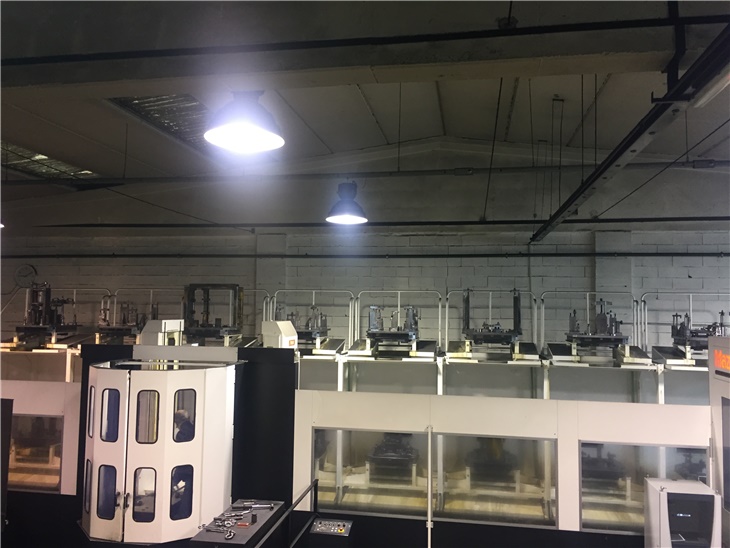

Workshop.

F.lli Severgnini has a production department specialized in machining with vertical work centres, horizontal work centres with two or more pallets, and horizontal with FMS on two levels, as well as a department dedicated to broaching and another dedicated to turning.

To ensure production control and final quality, details are checked using two HEXAGON DEA three-dimensional machines in a dedicated room, as well as on-board machine controls with the aid of appropriate measuring instruments. A streamlined organizational process over time allows checks both during production start-up and at regular intervals during the entire batch processing.

LIST OF MACHINE

Mazak H630N - Number of pallets: 2

X axis: 1000

Y axis: 800

Z axis: 750 (+200 pallet center)

Maximum cylinder allowed: 900xH950

Table size: 630X630 capacity 1200 Kg

ISO: 50

Spindle revs: 35-7000 turns/min.

Number of tools in store: 40

Table position: 360 1°

Renishaw head: NO

Mazak H630N - Number of pallets: 2

X axis: 1000

Y axis: 800

Z axis: 750 (+200 pallet center)

Maximum cylinder allowed: 900xH950

Table size: 630X630 capacity 1200 Kg

ISO: 50

Spindle revs: 35-7000 turns/min.

Number of tools in store: 40

Table position: Continue

Renishaw head: NO

Mazak H400N - Number of pallets: 2

X axis: 560

Y axis: 510 (+30 pallet plane)

Z axis: 510 (+100 pallet center)

Maximum cylinder allowed: 610xH600

Table size: 400X400 capacity 200 Kg.

ISO: 40

Spindle revs: 40-10000 turns/min.

Number of tools in store: 30

Table position: 1° Degree

Renishaw head: NO

Mazak VTC20CB - Number of pallets: 2

X axis: 560/1660

Y axis: 510

Z axis: 510

ISO: 40

Spindle revs: 20-7500 turns/min.

Number of tools in store: 48

Renishaw head: NO

Mazak VTC20CB - Number of pallets: 2

X axis: 560/1660

Y axis: 510

Z axis: 510

ISO: 40

Spindle revs: 20-7500 turns/min.

Number of tools in store: 48

Renishaw head: NO

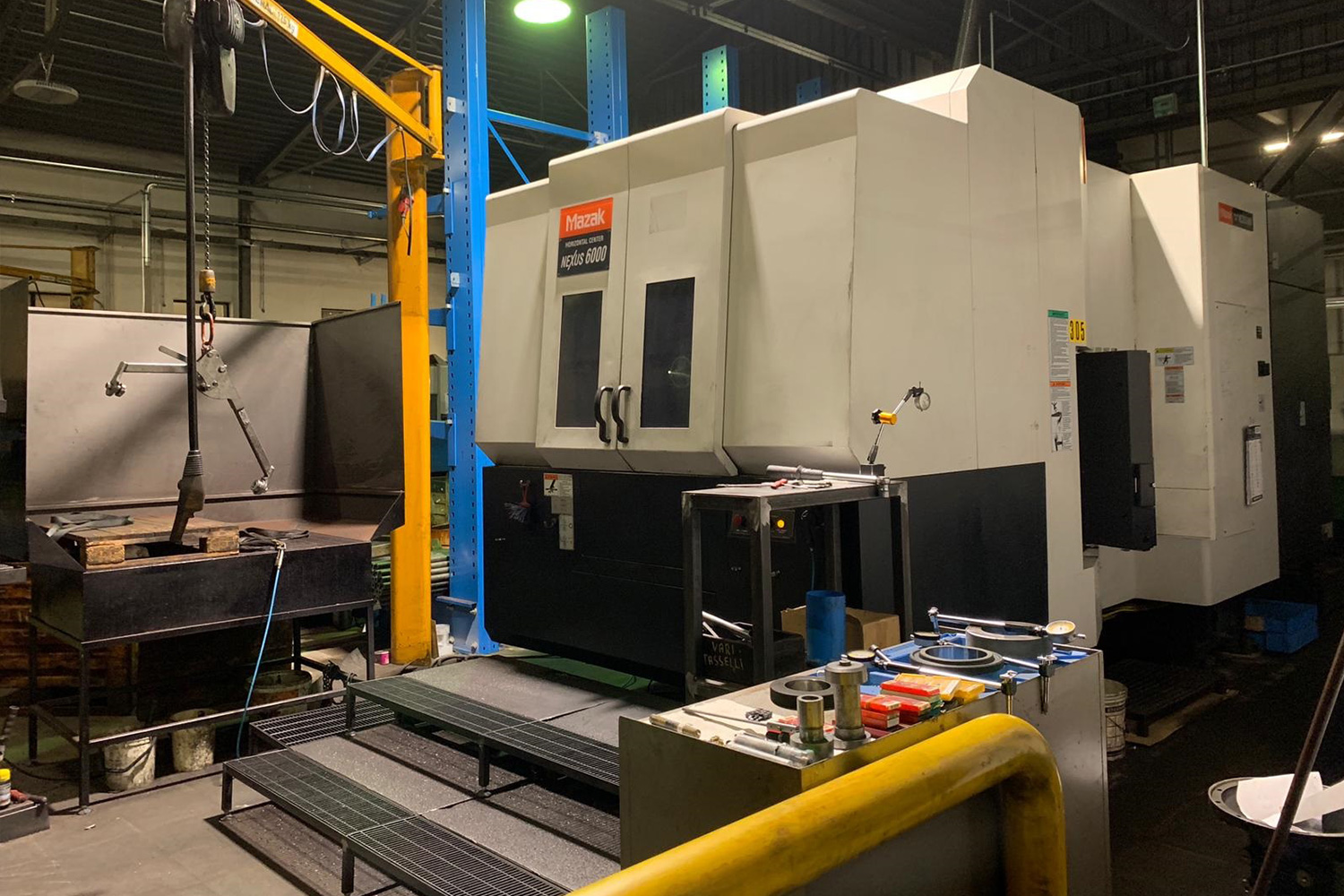

Mazak NEXUS 6000 - Number of pallets: 2

X axis: 800

Y axis: 800 (+100 pallet plane)

Z axis: 800 (+150 pallet center)

Maximum cylinder allowed: 900xH1000

Table size: 500x500

ISO: 50

Spindle revs: 35-7000 turns/min.

Number of tools in store: 43

Spindle motor: 36 kw (50 Hp)

Table position: 360.000 (0,001 Degree)

Renishaw head: SI

Mazak NEXUS 6000 - Number of pallets: 2

X axis: 800

Y axis: 800 (+100 pallet plane)

Z axis: 800 (+150 pallet center)

Maximum cylinder allowed: 900xH1000

Table size: 500x500

ISO: 50

Spindle revs: 35-10000 turns/min.

Number of tools in store: 43

Spindle motor: 36 kw (50 Hp)

Table position: 360.000 (0,001 Degree)

Renishaw head: SI

Mazak FH6800 - Number of pallets: 6

X axis: 1050

Y axis: 800 (+100 pallet plane)

Z axis: 880 (+150 pallet center)

Maximum cylinder allowed: 1050xH1000

Table size: 630x630 capacity 1500 Kg.

ISO: 50

Spindle revs: 35-10000 turns/min.

Number of tools in store: 120

Spindle motor: AC 36 kw (50 Hp)

Table position: 360.000 (0,001 Degree)

Renishaw head: SI

Mazak FH6800 - Number of pallets: 6

X axis: 1050

Y axis: 800 (+100 pallet plane)

Z axis: 880 (+150 pallet center)

Maximum cylinder allowed: 1050xH1000

Table size: 630x630 capacity 1500 Kg.

ISO: 50

Spindle revs: 35-8000 turns/min.

Number of tools in store: 120

Spindle motor: AC 36 kw (50 Hp)

Table position: 360 (1° Degree)

Renishaw head: SI

Mazak FH8800 - Number of pallets: 12

X axis: 1300

Y axis: 1100(+100 pallet plane)

Z axis: 1000(+150 pallet center)

Maximum cylinder allowed: 1250xH1250

Table size: 800x800 capacity 2200 Kg

ISO: 50

Spindle revs: 35-7000 turns/min.

Number of tools in store: 160

Spindle motor: AC 38 kw

Table position: 360.000 (0,001 Degree)

Renishaw head: SI

Mazak FH880 - Number of pallets: 2

X axis: 1300

Y axis: 1100 (+50 pallet plane)

Z axis: 1000 (+200 pallet center)

Maximum cylinder allowed: 1250xH1250

Table size: 800x800 capacity 2200 Kg

ISO: 50

Spindle revs: 35-7000 turns/min.

Number of tools in store: 40

Spindle motor: AC 36 kw (50 Hp)

Table position: 360 (1° Degree)

Renishaw head: SI

Mazak FH580 - Number of pallets: 6

X axis: 710

Y axis: 610 (+50 pallet plane)

Z axis: 660 (+150 pallet center)

Maximum cylinder allowed: 700xH730

Table size: 500x500 capacity 500 Kg.

ISO: 40

Spindle revs: 35-12500 turns/min.

Number of tools in store: 120

Spindle motor: 22 kw

Table position: 360 (1° Degree)

Renishaw head: SI

Mazak HCN 6800 - Number of pallets: 12

X axis: 1050

Y axis: 900 (+100 pallet plane)

Z axis: 980 (+100 pallet center)

Maximum cylinder allowed: 1050XH1300

Table size: 630x630 capacity 1500 Kg.

ISO: 50

Spindle revs: 35-1000 turns/min.

Number of tools in store: 120

Spindle motor: AC 38 kw

Table position: 360.000 (0,001 Degree)

Renishaw head: SI

Mazak HCN 8800 - Number of pallets: 20

Number of pallets: 20

X axis: 1400

Y axis: 1200(+100 pallet plane)

Z axis: 1325 (+100 pallet center)

Maximum cylinder allowed: 1250xH1250

Table size: 800X800 capacity 2200 kg.

ISO: 50

Spindle revs: 35-8000 turns/min.

Number of tools in store: 348

Spindle motor: 38 kw

Table position: 360 (1° Degree)

Renishaw head: SI

Mazak FH680 - Number of pallets: 2

X axis: 1050

Y axis: 800 (+100 pallet plane)

Z axis: 825 (+200 pallet center)

Maximum cylinder allowed: 1050xH1000

Table size: 630X630

ISO: 50

Spindle revs: 1500

Number of tools in store: 80

Spindle motor: AC 22 kw

Table position: 360

Renishaw head: SI

Vertical broaching machine "Colonial RD-30-66"

Three positions

Run: 1650mm

Thrust: 2500kg

Maximum diameter of broaching: 110mm

Vertical broaching machine "Magnaghi D 25-1600"

Three positions

Run: 1900mm

Thrust: 2500kg

Maximum diameter of broaching: 110mm

Vertical broaching machine "Varinelli 900"

One position

Run: 900mm

Numerical control lathe "PPL VEGA"

Maximum rotating diameter: 880mm

Maximum recommended diameter: 350mm

Maximum turning length between centres: 560mm

Bar passage diameter: 78mm

Self-centring hole diameter: 95mm

Spindle speed: 2600 turns

Numerical control lathe "GOODWAY GCL3"

Maximum rotating diameter: 510mm

Max turning diameter: 330mm

Max turning length between the tips: 600mm

Bar passage diameter: 75mm

Self-centring hole diameter: 90mm

Spindle speed: 3000 turns

Numerical control lathe "GOODWAY GCL2L"

Maximum rotating diameter: 280mm

Max turning diameter: 220mm

Max turning length between the tips: 600mm

Bar passage diameter: 46mm

Self-centring hole diameter: 55mm

Spindle speed: 3500 turns

Lathe Mazak SQT10MS

Maximum rotating diameter: 230mm

Max turning length between the tips: 300mm

Spindle hole diameter: 60mm

Spindle speed: 35-6000 turns

With counter spindle and driven tools

Processes.

F.lli Severgnini develops production processes starting from designs/projects provided by customers.

Particular attention is given, in this first phase of process creation, to the choice of machinery that will be used, the creation of mechanical clamping equipment, the choice of tools and the type of checks to be carried out. The final process must guarantee a product that meets the highest quality standards required by customers. The synergic processing of the various departments allows the development of details suitable for each and every need: precision and speed of execution make F.lli Severgnini a reliable partner for prestigious brands in the agricultural machinery, automotive, hydraulic and railway sectors.